💧 Water Pressure Loss & Pipe Pressure Drop Calculator

Estimate pressure loss in kPa, PSI, and head loss (meters) based on flow, diameter, pipe material, and pipe length.

Water Pressure Loss Calculator (Pipe Pressure Drop Calculator)

Created by James S. Lockwood

With a background in botany and ecological sciences, James specializes in creating practical tools and resources to help gardeners, farmers, and plant enthusiasts optimize their green spaces.

Table of Contents

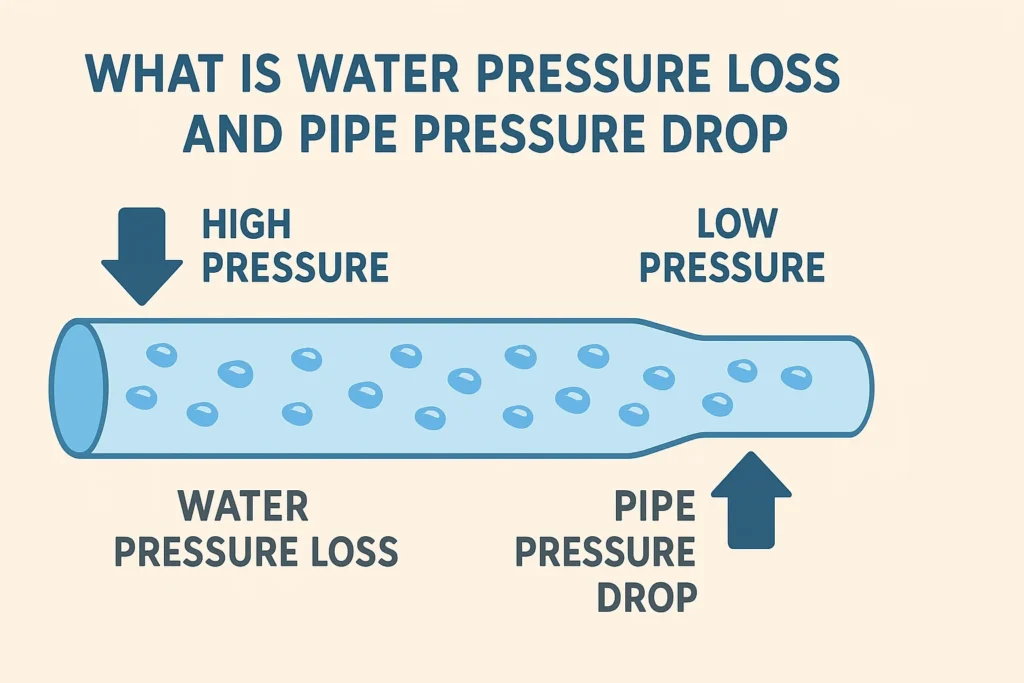

What Is Water Pressure Loss and Pipe Pressure Drop?

Most of us have experienced it—the disappointing trickle from a hose that once flowed powerfully. Whether you’re managing a drip irrigation system or simply trying to understand your household plumbing, water pressure loss is an issue worth exploring.

At its core, pressure loss refers to the reduction in force as water travels through a pipe. It’s often caused by friction, resistance from pipe walls, and turbulence from elbows or fittings. Technically speaking, this phenomenon is also known as pipe pressure drop—and while the terms are often used interchangeably, they can take on different nuances depending on the context.

Some call it “water pressure loss,” especially in irrigation and home plumbing. Others prefer “pipe pressure drop,” a term more common in industrial settings. But regardless of the terminology, the result is the same: your water doesn’t arrive at the other end with the force you expected. That’s why a good water pressure loss calculator is essential for planning any efficient piping system.

Why Water Pressure Drops in Pipes?

There are several factors that contribute to pressure loss: pipe length, diameter, material, and flow rate. The longer the pipe, the more friction builds. Narrower pipes increase velocity, which raises friction again. And don’t forget the fittings—every elbow and tee can create tiny swirls that sap pressure along the way.

But here’s the interesting part: in some systems, pressure loss is not only expected—it’s acceptable. A drip irrigation system, for example, is designed with gradual pressure reduction in mind. However, if your last few emitters are barely dripping, you’ve probably crossed the line into “problematic.”

So, how do you strike that balance? That’s where a pipe pressure drop calculator becomes your best friend. It allows you to estimate the PSI loss based on specific variables like pipe type, flow rate, and distance.

How to Use a Water Pressure Loss Calculator?

Using a water pressure loss calculator might sound technical, but it’s surprisingly intuitive when done right. Most calculators ask for just a few details:

Pipe material (PVC, PE, copper, etc.)

Internal diameter

Flow rate (GPM or LPM)

Pipe length (in feet or meters)

The calculator then estimates PSI drop over the given distance. It uses the Hazen-Williams equation (popular in irrigation).

If you’re building or optimizing a drip system, check out the Drip Irrigation Pump Calculator to ensure your pump can overcome the estimated loss. Similarly, if you’re planning emitter layout, the Drip Irrigation Flow Rate Calculator can help determine how much water you’re pushing through in the first place.

How is Pipe Pressure Drop Calculated?

Here’s a simplified version of what’s happening when calculating pressure loss:

🔢 Hazen-Williams Formula

PSI loss = 4.52 × (Flow / (C × Diameter2.63)) × (Length / 100)

Where:

- C = roughness coefficient (PVC ~ 150, Steel ~ 100)

- Flow = GPM (gallons per minute)

- Diameter = pipe inner diameter (inches)

- Length = pipe length (feet)

Of course, that’s just one of many formulas. Some calculators use the Darcy-Weisbach equation, which is better suited for turbulent flow or when using metric units. It depends on the system you're working with—but Hazen-Williams is more than enough for most irrigation and residential uses.

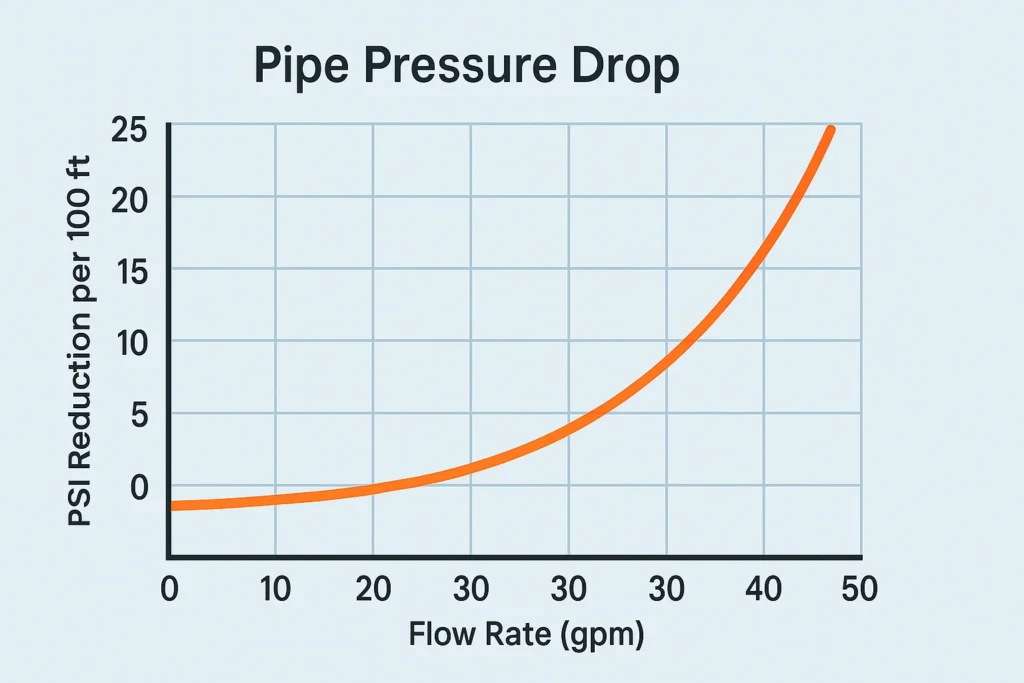

Why PSI Drops in Long Pipes? PSI Loss per 100 Feet

The longer the pipe, the greater the opportunity for friction to sap energy from the water. Even with smooth materials like PVC or polyethylene, friction builds steadily with distance.

For example:

A ½” pipe might lose 6–8 PSI per 100 ft at moderate flow.

A 1″ pipe at the same flow might only lose 1–2 PSI.

But friction isn’t linear. As flow rate increases, the loss grows exponentially. That’s why a small bump in flow can lead to a surprisingly large PSI drop over long runs. It’s also why systems that seem “fine” at 50 ft may completely fail at 250 ft.

What complicates things further is fittings—every elbow, valve, or tee adds extra resistance, known as equivalent length. A 90° elbow might add the friction of 10–15 extra feet of pipe. It’s easy to underestimate these effects.

What’s Considered Normal Water Pressure?

Most residential systems operate between 40–60 PSI. Below 30 PSI, performance begins to suffer, and below 20 PSI, many sprinklers and emitters won’t function properly at all. That said, in some low-pressure systems (like gravity-fed irrigation), even 10 PSI might be considered acceptable.

So how much pressure drop is too much? It depends. For drip irrigation, a 5–10 PSI loss might be fine across 200–300 feet. For overhead sprinklers, even a 2 PSI difference can cause noticeable changes in spray radius. Ultimately, the “acceptable” amount of loss is a judgment call—but one that should be made with data, not guesswork.

There’s no universal PSI that fits all situations—but we can define good working ranges. If you’re unsure where your system stands, try our Drip Irrigation Pump Calculator to ensure your pump is matched to your line layout and total loss.

Drip Irrigation

Ideal Pressure Range: 20–30 PSI

Sprinklers / Turf

Ideal Pressure Range: 30–50 PSI

Residential Plumbing

Ideal Pressure Range: 40–60 PSI

Commercial / Industrial

Ideal Pressure Range: 60–80 PSI or more

How to Reduce Water Pressure Loss in Pipes?

While you can’t eliminate friction loss entirely, there are several ways to manage it effectively:

Use larger diameter pipes: Doubling the diameter significantly reduces friction. In many systems, upsizing from ¾” to 1″ is a simple way to regain 5–10 PSI over a few hundred feet.

Minimize bends and fittings: Fewer elbows = fewer pressure penalties.

Lower the flow rate: Slower water faces less turbulence.

Choose smoother materials: PVC and HDPE usually outperform metal pipes in terms of friction.

Split the system: Break long runs into smaller branches to keep pressure more uniform.

There’s always debate around over-engineering. Some argue that for small systems, sticking to basic sizing works just fine. Others insist on maximizing efficiency no matter the scale. The right approach may depend on your water source, terrain, and budget.

FAQ: Water Pressure Loss Calculator (Pipe Pressure Drop Calculator)

How do I calculate water pressure loss?

You can use a water pressure loss calculator by entering pipe length, diameter, flow rate, and material. The tool estimates PSI drop based on friction formulas.

How much PSI is lost per 100 ft?

It depends on flow rate and pipe size. A ½” pipe at 4 GPM may lose 6–8 PSI per 100 ft. A 1″ pipe at the same flow might lose only 1 PSI.

Is pipe pressure drop normal?

Yes, a certain amount is always expected. The question is whether your system can still function properly after the drop.

What is the legal minimum water pressure for a home?

In the U.S., 20 PSI is typically the legal minimum for residential supply—though most homes aim for at least 40–45 PSI.

Does elevation affect water pressure?

Absolutely. Every 2.31 feet of vertical rise causes a 1 PSI drop. For sloped properties, this matters more than pipe friction.

Final Thoughts

There’s no perfect formula for every situation. One person’s excessive PSI loss might be another’s acceptable margin. That’s why tools like our water pressure loss calculator exist—not just to give answers, but to support informed decisions. Combine that data with real-world testing, and you’ll strike the right balance between theory and practicality.

For more technical guidance, consider reviewing this pipe friction reference chart from Engineering Toolbox.

Or if you’re setting up a full drip system, start with our Drip Irrigation Calculator Hub to find everything from pump sizing to run time and flow rate.